In an economy disrupted by COVID-19, companies need to get products to market quicker than ever before. Accelerating a trend that had already been growing, COVID-19 has made speed to market critical for business survival. Sometimes this is because a company has pivoted due to falling demand or restrictions on the products they usually sell. Others have seized opportunities to create products that meet new consumer needs.

Some agile businesses have seized new opportunities by getting products to market within a few weeks. For instance, the UK-based hand sanitizer companies Just Sanitise and ClearWater Hygiene both launched in Q2 2020, and have since achieved seven-figure turnover.

Shrinking Project Lifecycles Stress Supply Chains

Whether you are pivoting to meet the new reality or you are launching something new, there is constant pressure to get new products onto the shop shelves faster. Ingredient suppliers will need to emphasize agility, quality, and consistency to cater to this focus on fast innovation.

For Sensient, this has sharpened our commitment to delivering both ingredient samples and orders on time.

“Running the Trains on Time”

At Sensient, we have an approach to on-time delivery and customer satisfaction that we call ‘Running the Trains on Time’. It is a metaphor for how we operate our business -- smoothly and effectively to best service our customers. This means we have focused organizational resources and internal metrics around delivering on-schedule.

Defining On-Time

We measure ourselves on late delivery based on the customer’s requested date, rather than dictating what their delivery date should be.

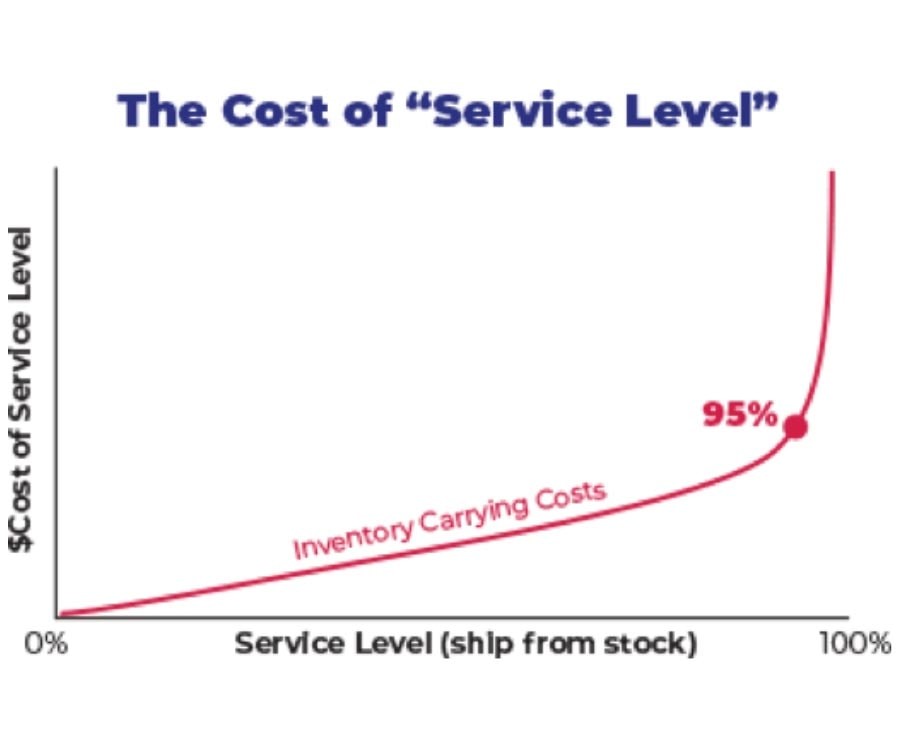

Our minimum on-time delivery expectation is 95%, and we challenge ourselves to meet this threshold to reduce our customers’ inventory costs and keep your manufacturing lines running. If Sensient ever falls below the 95% level, it’s flagged in our system and tracked for immediate improvement.

Sensient always offers full transparency on this topic, and if you are a current customer and interested in seeing your on-time delivery report, we are happy to provide our records. We encourage all our customers to track the percentage of orders that we deliver on time and to compare that to the performance of their other suppliers.

Vertical Integration

A key factor that equips us to deliver on time is our vertically integrated approach. Whereas many other colorants suppliers have a business model based on buying and reselling premade products, we manufacture over 90% of what we sell at our own facilities.

When it comes to natural colors and ingredients, Sensient’s investments in Our Global Agronomy Program enable us to add value to over 80% of our botanical colors through our vertically integrated supply chain, minimizing some of the supply challenges commonly associated with horizontal supply chains.

Global Presence

With Sensient, our customers are not depending on a manufacturing site an ocean away. We have manufacturing footprints throughout North America, South America, Europe, Asia-Pacific, and beyond, which means we manufacture near you – wherever you are.

For your next speed-to-market product development, request a sample from Sensient.